- Stock: In Stock

- SKU: 900-0002A

More from this brand

MakerBot Method X 3D Printer

Method X 3D Printer from MakerBot is a production workstation.

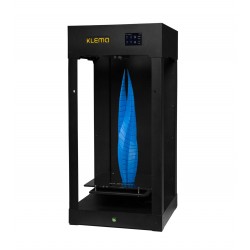

MakerBot introduced its Method X 3D printer, which is presented as a professional, high-performance, out-of-the-box 3D printer that solves a wide range of complex tasks without the extra effort. With two interchangeable modular extruders equipped with smart sensors, Method X offers fast 3D printing up to 2x faster than leading desktop counterparts. Its heated to 110 °C air-circulated working chamber with a volume of up to 190 x 190 x 196 mm creates the ideal conditions for high-precision printing of complex and durable parts made from engineering plastics ABS and other materials. Like the other 3D printers in the series, Method X is designed using patents from Stratasys to provide finished product dimensional accuracy, quality and reliability comparable to industrial printers.

Best for production:

- Manufacturing tools.

- End-use parts.

- Functional prototypes.

Method X Features

Method X technologies include professional components for a seamless CAD to Part workflow.

- Closed working chamber heated with circulation to 110 °C.

- Maximum extruder temperature 300 °C.

- Sealed compartments for dry storage of materials.

- Precision soluble substrates.

- Heavy-duty frame that eliminates vibration and body deformation.

- Modular high performance extruders.

- 21 built-in sensors and automation functions.

- Remote monitoring and control over Wi-Fi.

- 25 compatible CAD file types.

- 5-inch full color capacitive touchscreen.

- Over 300,000 hours of reliability testing on over 150 printers.

To meet rigorous industry standards, MakerBot has moved away from the open source tradition by offering a series of printers based on a completely new architecture. The MakerBot Method X offers engineers and designers the industrial productivity and flexibility to bring ideas to life quickly at an affordable price.

Supported consumables

With an enclosed 110 °C preheat oven and interchangeable modular extruders that heat up to 300 °C, Method X has a wide range of materials available. From traditional PLA and ABS, to various durable and specialty materials TOUGH, PETG, Nylon, ASA, Durabio, PC, as well as reinforced plastics such as N12 Carbon Fiber, ABS Carbon Fiber, ABS Kevlar, and soluble support materials.

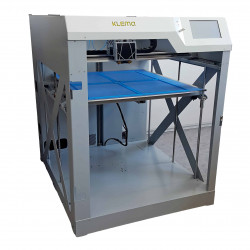

Robust frame construction

To achieve stability and accuracy of printing, it is necessary to compensate for deformations and vibrations of the 3D printer body. To prevent them, the MakerBot Method X design is optimized with an ultra-rigid metal frame. It runs the entire length of the body to compensate for bends. Less flex means more stable prints with more detail accuracy and fewer bounces.

Print durable and accurate parts quickly

The Dual Performance high-performance extruder system is designed from the ground up to speed up print times and deliver precision up to ± 0.2 mm per part. Intelligent sensors for material management and print security. Each printer extruder contains a set of sensors that detect problems such as filament breakage or plastic jams in the extruder during the entire printing period.

The 19:1 gear system provides the force required to feed the plastic filament evenly into the nozzle. The heated working chamber and table, as well as a number of sensors, carry out a controlled temperature regime during the entire printing time. They ensure the quality of every layer, starting from the first. Uniform, controlled cooling of the part during printing results in dimensional accuracy and improved layer adhesion. Uncompromising adhesion of the layers makes the part strong in the Z-axis without deformation or twisting.

The elongated thermal core increases the heat distribution, and as a result, reduces the heating time to 60 seconds.

The dual extrusion system in MakerBot Method X, when used in conjunction with Soluble PVA, can create complex geometries.

Included Extruders:

- Model 1XA Extruder

- Support 2XA Extruder

Automated industrial printing system

MakerBot Print software works with 25 types of CAD files - work with the programs you are familiar with. Own Cloud Management project exchange platform. Remote printer management and printing, automated service and support procedures. Full CAD integration with AUTODESK Fusion 360, AUTODESK Inventor and Solidworks.

Optimized material storage

Method X offers a sealed material compartment in dry environments as a way to keep materials moisture stable. This is an important parameter that directly affects the print quality, the control of which was previously only available in industrial 3D printers.

A set of built-in sensors ensures that your material is kept in an optimal environment.

The printer's smart material management system controls the loading and self-feeding of materials to the extruder. The user just needs to insert the material and the printer does the rest.

Exceptional and reliable performance

The MakerBot X 3D Printer delivers industrial-grade performance at three times the cost of 1 year of operation for an industrial 3D printer. Using 3D printing to reduce design risks, testing prototypes and precision engineering parts, minimize costs later in the production cycle and enable faster time-to-market.

Buy 3D printer MakerBot Method X in Poland

| Printer Options | |

| Printing technology | FDM |

| Minimum layer height (micron) | 20 |

| Build Field (mm) | 190x190x196 (152x190x196 см for dual printing) |

| Ø of plastic (mm) | 1,75 |

| Print temperature (°C) | Above 270 |

| Number of extruders | 2 |

| Chamber type | Closed |

| Heating the chamber | Yes |

| Plastic drying | Yes |

| Autocalibration | Yes |

| Feeder type | Direct |

| Other options | |

| Nozzle Diameter (mm) | 0,4 |

| Printing accuracy (µm) | 200 |

| Print speed (mm/s) | Up to 2x faster than desktop 3D printers Max Material Flow Rate: ~50 mm³ per sec |

| Maximum carriage speed (mm/s) | Up to 500 |

| Maximum nozzle temperature (°C) | 300 |

| Maximum chamber temperature (°C) | 110 |

| Platform material | Flexible Steel Build Plate Reusable Grip Surface |

| Extruder Thermal Core Length (mm) | 48,2 |

| Max Extruder Drive Torque (Newtons) | 200 |

| Printer Automation | Automatic Z Calibration, Automatic Nozzle Calibration, Automatic Material Loading |

| Supported Materials | PLA, TOUGH, PETG, PETG ESD, PETG CF, Metal UF 316L, Nylon, N6 Carbon Fiber, N12 Carbon Fiber, SEBS 95A, ABS, ABS-R, ABS Carbon Fiber, ABS EC, ABS ESD, ABS Kevlar, ASA, Durabio, PC-ABS, PC-ABS FR, PC PBT, Polylite, Polymax PC, Polymax FR, PVA, RapidRinse, SR-30 |

| Operating system | Windows (7, 10) / Mac OS X (10.9+) |

| Control | 5" Full-Color Capacitive Touch Screen |

| Body material | Aluminum Die Cast Base Extruded Aluminum Uprights Steel Weldment Gantry Frame |

| Video camera | Yes |

| Camera Resolution (pixels) | 640x480 |

| Additional Information | Print Modes Tuned and Optimized for: 100 microns - High Quality Print Mode (Coming Soon) 200 microns - Balanced Print Mode |

| Features | Closed working chamber heated with circulation to 110 °C. Maximum extruder temperature 300 °C. Sealed compartments for dry storage of materials. Precision soluble substrates. Heavy-duty frame that eliminates vibration and body deformation. Modular Dual Performance Extruders. 21 built-in sensors and automation functions. Remote monitoring and control by Wi-Fi. 25 compatible CAD file types. 5-inch full color capacitive touchscreen. Over 300,000 hours of reliability testing on over 150 printers. |

| Supported file types | MakerBot (.makerbot), STL (.stl), SolidWorks (.sldprt, .sldasm), InventorOBJ (.ipt, .iam), IGES (.iges, .igs), STEP AP203/214 (.step, .stp), CATIA (.CATPart, .CATProduct), Wavefront Object (.obj), Unigraphics/NX (.prt), Solid Edge (.par, .asm), ProE/Creo (.prt, .asm), VRML (.wrl), Parasolid (.x_t, .x_b) |

| Software | MakerBot Print, MakerBot Mobile |

| Connectivity | USB Drive, USB, Ethernet, WiFi |

| Power supply | 100 - 240 V | 8.1A - 3.4A, 50 / 60 Hz | 800 W max |

| Storage Temperature (°C) | 0 - 38 |

| Weight Netto (kg) | 29,5 |

| Dimensions Assembled (mm) | 437x413x649 |

| Weight Brutto (kg) | 37,1 |

| Dimensions Brutto (mm) | 765x500x555 |

| Manufacturer country | USA |

| Warranty | Free 1-Year Extended Warranty Supported Plans: MakerCare Gold (2 Years), MakerCare Platinum (3 Years) |

| Suggested Operating Environment | |

| Operating Temperature Range (°C) | 15 - 26 |

| Operating Humidity Range (%) | 10 - 70 |