- Stock: In Stock

More from this brand

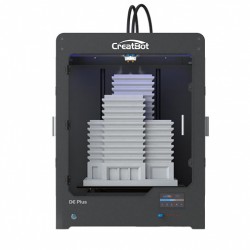

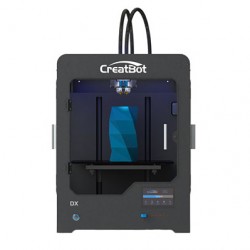

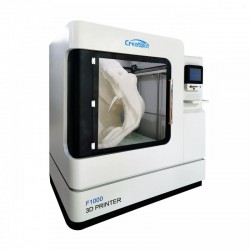

3D Printer CreatBot PEEK 300

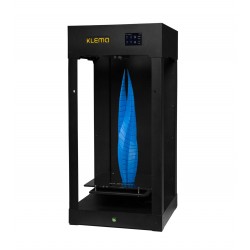

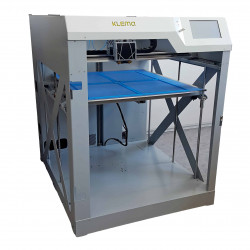

CreatBot PEEK-300 is an industrial 3D printer designed for medicine, surgery, industrial production. Produces printing of high-performance materials: engineering plastics, materials with a high melting point, ultra-PEEK materials. The printer is equipped with highly efficient thermal control, direct annealing and cooling systems. Heat and cooling are perfectly balanced, allowing printing from 0.04 mm layer thickness for both common plastics and highly deformable materials.

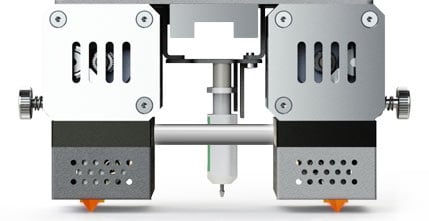

The print head with dual extruder and nozzle temperatures up to 500 °C allows you to work with a wide range of materials.

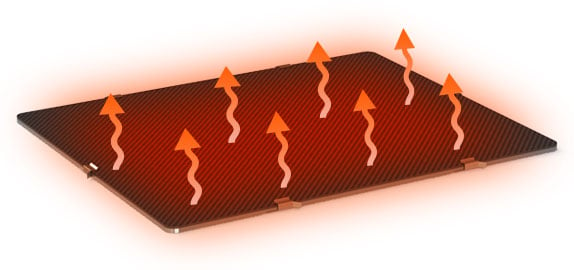

The print bed with temperatures up to 200 °C allows large models to be produced without deformation.

A chamber temperature of 120 °C also ensures the stability of the product without deformation or cracking.

Triple thermal insulation of the chamber ensures safety and economy.

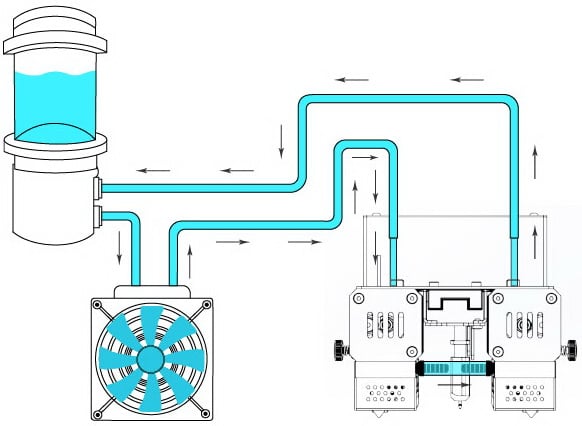

The dual cooling system is efficiently balanced and operates by circulating fluid and air flow.

The direct annealing temperature of 0-400 °C ensures processing without deformation and cracking of large-sized products made of functional materials.

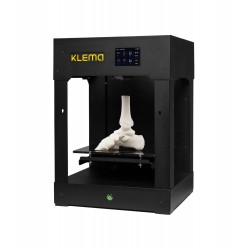

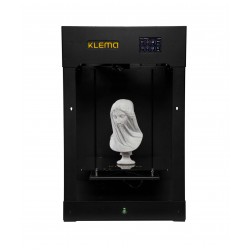

Before annealing

After annealing

Specifications 3D Printer CreatBot PEEK300

| Printing | |

| Construction field | 300 * 300 * 400 mm |

| Print accuracy | 0.04 mm - 0.4 mm |

| Thread diameter | 1.75 mm |

| Number of nozzles | Two extruders |

| Print speed | 10-150 mm/s |

| Nozzle diameter | 0.4 mm (0.3 ~ 1.0 mm optional) |

| Types of materials | Engineering plastics: PLA, PC, ABS, PA6, PETG, PVDF, TPU, FLEX. TPE. ABS. ASA, etc. High temperature materials: PPSU, PEI (ULTEM), PA12, PSU, PPS, PA-CF, POM, PP Ultra-performance materials: Medical PEEK, PEEK, CF-PEEK (Carbon fiber), GF-PEEK ( glass fiber), etc. |

| Software | |

| Software Bundle | Creatware, Simplify3D, Cura, Slice3r |

| operating system | Win7 / 8/10, MacOS |

| Files for printing | STL, OBJ, AMF, Gcode |

| Special functions | |

| Disconnect recovery | Resuming printing from where it stopped |

| Filament sensor | Automatic stop if thread runs out |

| Direct annealing system | The annealing process is instantly controlled during printing. It aims to deliver the highest quality parts in one go without warping and cracking printing from large functional materials |

| Thermal insulation | Triple thermal insulation |

| Emergency stop button | Emergency stop support |

| High temperature accessories | High temperature resistance motors, linear guides, belts and chains ensure long lasting high temperature printing |

| Temperature | |

| Maximum nozzle temperature | 500 ℃ |

| Chamber temperature | 120 ℃ |

| Platform temperature | 200 ℃ |

| Annealing temperature | 0 ~ 400 ℃ |

| Mechanics | |

| Cooling | Air pump cooling and water cooling |

| Platform | PCB aluminum + PEEK print board |

| Positioning accuracy | XY axis 0.01mm, Z axis 0.0025mm |

| Extruder | Direct drive |

| Design | Fully enclosed hot cell |

| Calibrating the table | Manual / Automatic |

| Electronics | |

| Input power | 100 ~ 230 V, 1.5 A |

| Maximum power | 3,000 W |

| Consumption | 24 V, 15 A |

| Screen | 4.3" full color touch screen, multi-language |

| Printing method | USB Connectivity / USB Disk |

| Size and weight | |

| 3d printer size | 650 * 600 * 750 mm |

| The weight | 100 kg |

| Printer size with packaging | 650 * 600 * 750 mm |

| The weight | 100 kg |

| Printer Options | |

| Printing technology | FDM |

| Minimum layer height (micron) | 40 |

| Build Field (mm) | 300*300*400 |

| Ø of plastic (mm) | 1,75 |

| Number of extruders | 2 |

| Chamber type | Closed |

| Heating the chamber | Yes |

| Plastic drying | No |

| Autocalibration | Yes |

| Feeder type | Direct |

| Other options | |

| Nozzle Diameter (mm) | 0,4 (optional 0,3 - 1,0) |

| Positioning accuracy (µm) | XY: 10; Z: 25 |

| Print speed (mm/s) | From 10 to 150 |

| Maximum nozzle temperature (°C) | 500 |

| Maximum chamber temperature (°C) | 120 |

| Heating the platform | Yes |

| Maximum platform temperature (°C) | 200 |

| Direct annealing temperature (°C) | 0 - 400 |

| Platform material | PCB aluminum + PEEK print board |

| Supported Materials | Engineering plastics: PLA, PC, ABS, PA6, PETG, PVDF, TPU, FLEX. TPE. ABS. ASA, etc. High temperature materials: PPSU, PEI (ULTEM), PA12, PSU, PPS, PA-CF, POM, PP Ultra-performance materials: Medical PEEK, PEEK, CF-PEEK (Carbon fiber), GF-PEEK (glass fiber), etc. |

| Operating system | Win 7/8/10, Mac OS |

| Control | 4.3'' full color touch screen, multi-language |

| Features | • Power outage: resume printing from where it was stopped • Thread breakage: automatic stop • The annealing process is instantly controlled during printing. It aims to provide the highest quality parts in one go without warping and cracking printing from large functional materials • Triple thermal insulation • Emergency stop button • High temperature resistance motors, linear guides, belts and chains provide long lasting high temperature printing • Air pump cooling and water cooling |

| Supported file types | STL, OBJ, AMF, G-CODE |

| Software | Creatware, Simplify3D, Cura, Slice3r |

| Connectivity | USB Connectivity/USB Disk |

| Power supply | 200~240V, 20A, 4600W |

| Weight Netto (kg) | 100 |

| Dimensions Assembled (mm) | 650*600*750 |

| Weight Brutto (kg) | 130 |

| Dimensions Brutto (mm) | 820*720*1080 |

-250x250.jpg)

-250x250w.jpg)